- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Author: Niccolo,Choi Lin Publish Time: 2025-05-12 Origin: Site

Neodymium magnets (NdFeB) as the most important Servo Motor Magnet are critical for servo motors due to their exceptional magnetic properties, which directly enhance motor performance, efficiency, and compactness.Here's why they are indispensable:

1. High Magnetic Strength

2. Improved Efficiency & Dynamic Response

3. Compact & Lightweight Design

4. Precision & Stability

5. Cost-Effectiveness in High-Performance Applications

Neodymium magnets enable servo motors to achieve high torque, efficiency, and miniaturization, making them irreplaceable in modern precision motion control systems.

Alternatives like SmCo (for extreme temps) or ferrite (for cost) exist but can't match NdFeB's balance of strength and compactness.

A servo motor is a high-performance motor used for precise control of position, speed, and torque in closed-loop systems. It is widely used in applications requiring high accuracy, rapid response, and reliability. Such as Robotics & Automation,CNC Machines & Manufacturing,Aerospace & Defense,Automotive & Electric Vehicles (EVs) and Medical Devices,Consumer Electronics and so on.it's widely used in our dayily life.

For example:The common range of servo motor speed is 1000-3000 revolutions per minute (rpm), with a maximum of 5000 rpm

Low inertia motor: The rated speed is mostly 3000 revolutions per minute, and the maximum can reach 5000 revolutions per minute.

Medium to high inertia motors: The rated speed is usually 1500 or 2000 revolutions per minute, with higher torque models having lower speeds.

Magnets are a critical component in servo motors, enabling precise motion control by interacting with electromagnetic coils to generate torque and position feedback. The type, strength, and placement of magnets directly impact motor efficiency, responsiveness, and accuracy.

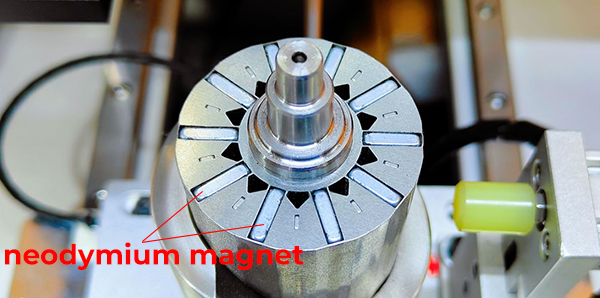

Yes, neodymium magnets (NdFeB) are widely used in various types of motors due to their exceptional magnetic strength, compact size, and energy efficiency. Here is how they're applied in different motor types and why they're preferred:

A. Servo Motors,Used for precise position/speed control (robotics, CNC machines).

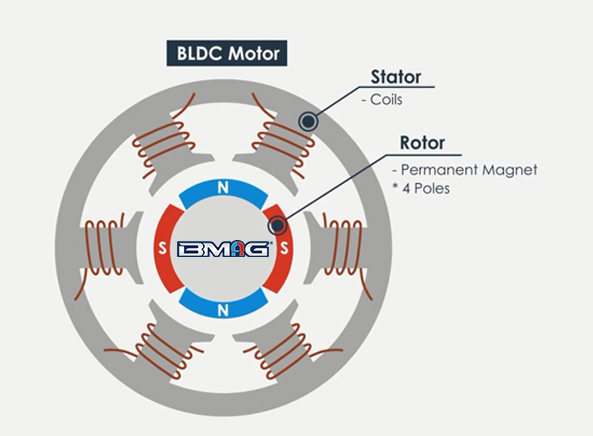

B. B. Brushless DC (BLDC) Motors,Common in drones, EVs, HVAC systems, and industrial drives.

C. Permanent Magnet Synchronous Motors (PMSM).Used in electric vehicles (Tesla, Toyota) and industrial automation.

D. Stepper Motorssome high-performance steppers use NdFeB for stronger detent torque (e.g., medical devices).

E. Direct-Drive Motors.Wind turbines, high-torque robotics (e.g., collaborative arms).

Magnets can affect servo motors in several ways, depending on how they interact with the servo's internal components. Here’s a breakdown of the effects:

1. Interference with the DC Motor (Inside the Servo)

Most servos contain a small DC motor with permanent magnets in its housing.

If an external magnet is brought close, it can:

Disrupt the magnetic field, causing erratic motor behavior.

Weaken or strengthen the motor's magnetic field, affecting torque and speed.

Cause misalignment of the motor’s brushes (if it’s a brushed motor), leading to inefficiency or failure.

2. Impact on the Potentiometer (Feedback Mechanism)

Traditional servos use a potentiometer to sense position.

A strong magnet near the potentiometer can:

Induce electrical noise, causing jitter or incorrect positioning.

Physically interfere with the wiper mechanism (if magnetic materials are inside).

The main differences between a servo motor and a regular motor (such as a standard DC or AC motor) lie in their control mechanisms, precision, and applications. Here’s a detailed breakdown:

Control Method

Servo Motor:Uses closed-loop control (feedback system) to adjust position, speed, or torque.

Contains an encoder, potentiometer, or Hall effect sensor to provide real-time feedback to the controller.

Corrects errors dynamically (e.g., if the motor is forced off-position, it tries to return).

Regular Motor (DC/AC/Stepper):

Typically open-loop (no feedback), meaning it runs blindly unless paired with an external sensor.

Example: A simple DC motor spins when power is applied but doesn’t know its position or speed unless monitored separately.

Stepper motors are an exception—they move in precise steps but lack real-time feedback unless equipped with an encoder.

Neodymium (NdFeB) magnets, the strongest type of permanent magnets commercially available, offer several key benefits when used in servo motors, particularly in brushless DC (BLDC) servos and high-performance brushed servos.

1. High Magnetic Strength

2. Improved Dynamic Response

3. Higher Efficiency & Energy Savings

4. Better Torque-to-Inertia Ratio

5. Compact & Lightweight Design

6. Wide Operating Temperature Range

While neodymium magnets offer superior strength and performance, they come with several drawbacks that must be considered, especially in servo motor applications:

1. Temperature Sensitivity. Lose magnetism at high temperatures.

Solution: High-temperature grades (e.g., N30SH, N42UH) with added dysprosium (Dy) or terbium (Tb) can withstand up to 200°C, but at a higher cost.

2. Brittle & Prone to Chipping/Cracking.

Solution: Protective coatings (e.g., nickel, epoxy) help, but careful handling is still required.

3. Corrosion Vulnerability,

Solution: Coatings (e.g., Ni-Cu-Ni plating, epoxy, gold, or parylene) improve corrosion resistance but add cost.

4. High Cost Compared to Ferrite Magnets

Price fluctuations can occur due to geopolitical factors (China dominates rare-earth supply).

Yes, but under normal conditions, the loss is very slow (typically less than 1% per decade). However, certain factors can accelerate demagnetization.

Neodymium magnets in servo motors retain strength for decades under normal use but can degrade quickly if:

Overheated (most common issue).

Standard grades (N35–N52): Start losing strength above 80–150°C, depending on grade.

Solution: Use high-temperature grades (e.g., N30SH, N42UH) for demanding environments

Exposed to strong reverse fields or physical damage.

Neodymium magnets have a coercivity rating (resistance to demagnetization). If an opposing field exceeds this, the magnet partially or fully demagnetizes.

Example: Placing a neodymium magnet near a stronger magnet with opposite polarity can weaken or erase its field.

Solution

Use high-coercivity grades (e.g., H, SH, UH, EH suffixes like N42SH).

Avoid close contact with opposing fields (e.g., in motors, ensure proper magnetic circuit design).

Shield the magnet with soft iron or steel to redirect stray fields.

The lifespan of a servo motor depends on multiple factors, ranging from environmental conditions to operational usage.Here’s a detailed breakdown of the key factors that influence longevity:

1.Operating Temperature & Heat Management

2.Load & Duty Cycle

3.Mechanical Wear (Gears, Bearings, Brushes)

4.Electrical Factors,Voltage Spikes/Surges,Improper PWM Signals.

For example:

Issue: Operating outside rated voltage causes overheating or insufficient torque.

Solution: Use voltage regulators/protection circuits.

The ideal neodymium (NdFeB) magnet for a servo motor depends on temperature resistance, coercivity (resistance to demagnetization), and torque requirements.

Below are the top grades for different servo applications:

Grades: N35, N42,Best For Hobbyist RC servos (plastic gears).and Low-power robotics (where overheating is unlikely). see below inlinks :

https://www.bwmagnets.com/N42-Cube-Magnet-pd46481765.html

Grades: N42SH, N45H, N48H,Best for High-Temperature Servos.

See below links :https://www.bwmagnets.com/Strong-Neodymium-Arc-Magnet-pd44597665.html

Shape:1. Arc Magnets/Curved Magnets (Best for Brushless Servo Motors - BLDC)

Shape:2. Rectangular Block Magnets (Common in Brushed & Coreless Servos)

The magnetization direction of neodymium magnets significantly impacts servo motor performance, influencing torque, efficiency, and control precision. Here’s how different magnetization orientations affect servo motors:

1. Radial Magnetization

Optimized for smooth rotation in brushless (BLDC) servo motors.

2. Axial Magnetization (Used in Disc/Ring Magnets)

Magnetic field runs parallel to the axis,Found in encoders, Hall sensors, or coreless brushed servos.

3. Multipole Magnetization

For High-Resolution Control,Increases position resolution (critical for precision servos).

Rectangular Block Magnet for Servo Motor

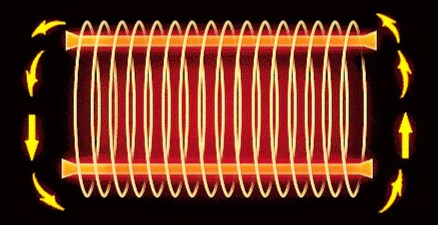

Magnetic flux (measured in Webers or Tesla) is the "flow" of the magnetic field through the motor’s components. It directly impacts torque, speed, efficiency, and control precision in servo motors. Here’s how:

Selecting the right supplier for neodymium (NdFeB) magnets is critical for ensuring performance, longevity, and cost-efficiency in servo motor applications. Here’s a step-by-step guide to finding a Servo Motor Magnet suppliers:

1.Industry Experience:

Look for suppliers with 5+ years in NdFeB magnets, especially those familiar with servo motor applications.

2.Customization Capability:

Can they provide arc, block, or ring magnets in specific grades (N42SH, N35AH)?

3.Certifications:

Check Quality Certifications,ISO 9001,RoHS/REACH,Magnetic Testing Reports.

Contact our customer service staff for more information

content is empty!

+86-574-87504597

+86-574-87506697

thomas03@bwmagnet.com